- Focus on product innovation and creating a niche to maintain quality and customer satisfaction.

- Stay updated with customer preferences and utilize new technologies and trends to stay ahead of the competition.

- Develop and implement efficient operational procedures to reduce costs while maintaining high-quality products and services.

- Prioritize regulatory compliance, safety, and human resource management.

- Leverage technology for efficiency, control, and productivity.

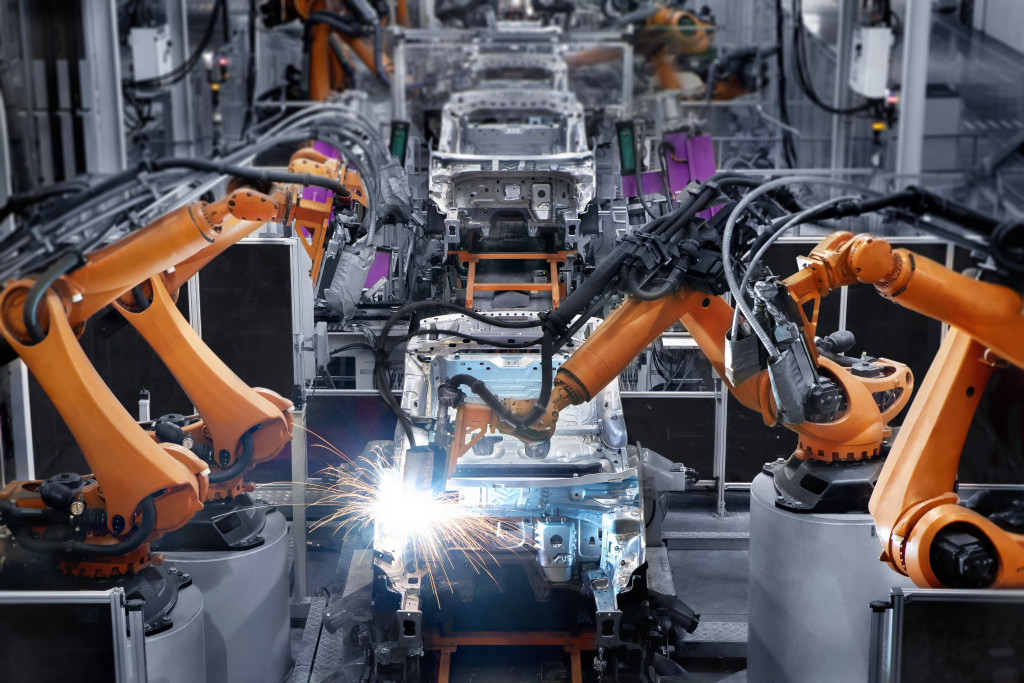

Entrepreneurship is growing unprecedentedly, and establishing manufacturing facilities is the next step to success. The manufacturing market’s value added is expected to reach US$3.09 trillion by 2023, with an annual growth rate of 3.02 percent. Manufacturing not only generates jobs and revenue, but it also contributes significantly to the economic development of a region.

However, the road to establishing a manufacturing facility can take time, with factors such as competition, cost of infrastructure, regulatory compliance, and supply chain management. Still, with the right approach and resources, businesses can overcome these barriers and reap the benefits of their investment in manufacturing.

Focus on Product Innovation

To remain competitive, a successful manufacturing facility must base its operations on continuous product innovation. Emphasize creating a high-quality product that stands out from industry standards.

Create a Niche

Focus on creating a niche for yourself and maintaining the product’s quality. This improves your product’s image, ensuring your customers keep coming back and that your product competes against similar products from other manufacturing facilities.

Stay Updated

To ensure product innovation remains at the center of your operations, keep up with trends and changes in customer preferences. Listen to feedback from customers and take note of their suggestions for improvements. If necessary, utilize new technologies and skills to stay ahead of the competition and continuously update your processes to maintain efficiency.

Establish Strategic Partnerships

Establishing strategic partnerships is crucial to empowering entrepreneurs to establish a manufacturing facility successfully and provide extensive resources, funding, and equipment. Collaborating with other manufacturing units develops and can create unique business ideas that firms can enjoy the benefits of partnerships, sharing resources and expertise. Collaboration ensures a sustainable supply chain management that enables firms to reduce costs and increase profit.

Access to New Markets

Partnerships with local manufacturers and businesses can help entrepreneurs access new markets, customers, materials, technology, and services. By working together, entrepreneurs are more likely to avoid financial crises or operational issues that could arise during manufacturing. This will also provide access to additional resources such as employee training programs, product marketing opportunities, and other capital for investments.

Prioritizing Regulatory Compliance and Quality

To successfully establish a manufacturing facility, it is essential to meet all regulatory requirements and adhere to industry standards. Entrepreneurs should also conduct due diligence by regularly testing products and ensuring the facility complies with all regulations. Consistently testing your products and ensuring compliance helps maintain quality control, avoid potential legal disputes, and avoid the risk of losing your customers’ trust.

Ensure Safety at the Facility

Safety should be a top priority when establishing a manufacturing facility. Entrepreneurs must ensure that fire safety standards, hazardous material handling protocols, and other workplace safety regulations are in place. To ensure the safety of the facility, you should work with a reputable industrial engineering consulting firm during the planning stage. The firm can conduct a comprehensive assessment of the facility and help develop safety protocols.

Leverage Technology

Revolutionary technologies, such as automation, cloud-based manufacturing software, and artificial intelligence (AI), can help businesses with efficiency, control, reduced labor cost, and increased productivity significantly. With the latest technology, businesses can scale up operations, improve production yields, and optimize manufacturing processes.

Automated Tools

In addition, technology can help businesses stay competitive by providing automated tools that allow them to monitor performance and measure the effectiveness of their operations. These tools can also provide insights into customer behavior and trends, helping businesses better understand their customers. This insight can be used to develop new marketing and sales strategies and product development.

Focus on Human Resource Management

A thriving manufacturing operation requires a skilled team that is adequately incentivized and motivated to work toward growth. Ensure to provide tools and training to improve productivity and offer incentives, such as bonuses, promotions, and short and long-term incentives to motivate staff.

Culture of Excellence

Efficient HR management sustains a company culture of excellence, helps develop employee skills, and leads to maximum productivity with minimum supervision. Regularly measure performance against goals and objectives to identify areas of improvement. Provide feedback, both positive and negative, as well as a clear path for career advancement.

Entrepreneurs looking to establish manufacturing facilities will undoubtedly face steep challenges, but the entire process is infinitely rewarding. By innovating new products, fostering strategic alliances with other businesses, focusing on regulatory compliance and quality, leveraging technology, and prioritizing human resources, businesses can overcome the stumbling blocks and set themselves on the path to success. Therefore, entrepreneurs must ensure that their manufacturing ventures prioritize these factors to achieve enduring success and carve out profitability in the competitive landscape.